BatchMaster Manufacturing for SAP Business One

Harness the power of the best combo ever for recipe/formula-based manufacturers!

BatchMaster Manufacturing for SAP Business One is a process manufacturing ERP solution for all your manufacturing ERP needs. It is an ERP built on SAP Business One, removing hurdles to growth and success by giving manufacturing capabilities and making it a one-stop solution for all the distribution, finance, manufacturing, quality and compliance needs.

Adheres to industry and regulatory compliance

Easily comply with COA, FDA, GHS, FSSAI, FSMA, EPA, and other norms with BatchMaster Manufacturing for SAP Business One for African Manufacturing Industries.

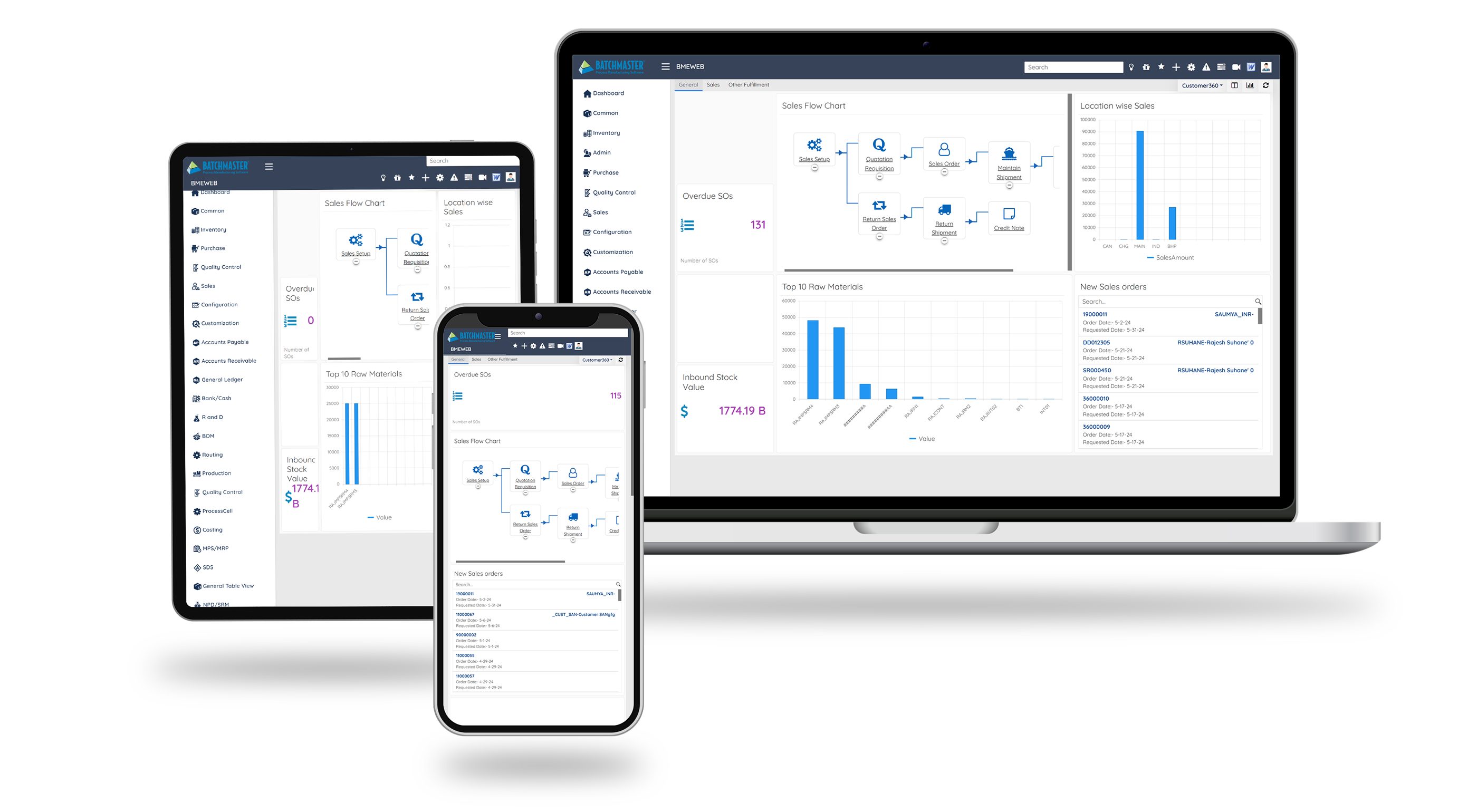

User-Friendly GUI

Seamless working experience with a single and uniform login, single database and interface, Google-style search, connection maps, alarms, and workflows.

Contemporary in its Approach

The team of experts and researchers always keeps a tab on the latest trends, and technological advancements, so that the product is always updated.

One Complete Solution

BatchMaster Manufacturing for SAP Business One is a complete solution designed to cater to the emerging and ever-changing needs of formula and recipe-based manufacturers of Africa.

Specially-Tailored For Your Industry

Specifically designed for African manufacturers to cater to their business nuances of formula-based industries like food, paint, pharmaceutical, coating, chemical.

BatchMaster SAP Business One ERP Add Ons:

To meet the most specific business needs, the performance of BatchMaster manufacturing for SAP Business One can be boosted with well-designed add-ons, such as:

Enables easy and remote execution of inventory transactions via handheld devices like iPads, mobile phones, tablets, and other such devices.

Manage your inventory not only up to warehouse level, but with greater control at bin level as well.

Why BatchMaster Manufacturing for SAP Business One?

- Built-on strong foundation of SAP Business One,

- Streamlines the entire supply chain

- Exceptionally perfect fit with industry-specific solutions

- Assures streamlined processes that are less risky

- Helps you to follow all industry regulations and best practices

- Offers real-time information flow

- Innovates products faster and cheaper

- Provides faster yet accurate business decisions

- Assists in effective business analytics and market study

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally,QuickBooks,Sage 50/100/200/300,SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs